Product Recommendation | Tired of Frequent Misjudgments with Traditional Sensors? Try This One!

Release time:2025-08-13

In complex background environments, traditional sensors often suffer from misjudgments and missed detections, which severely slow down production efficiency and lead to inconsistent product quality. Moreover, when detecting tiny objects, highly reflective objects, or in harsh working conditions, traditional sensors can hardly meet the demands of modern industrial production for high precision and efficiency.

Heyi ZL-BG30 square laser photoelectric sensor with background suppression is designed to tackle these industry challenges. It can break through complex background interference, accurately capture tiny and highly reflective targets, and stand firm in harsh working conditions, safeguarding efficient and high-quality production. It uses laser as the light source, emitting a highly concentrated laser beam to precisely illuminate the target object.

Detection Principle

When the laser beam comes into contact with the target object, reflected light is generated. The sensor accurately determines the position and state of the target object by capturing changes in the intensity and angle of the reflected light.

Product Features

Laser light source, small light spot enables precise detection of tiny objects

Optional small point spot or linear light spot according to application needs

With background suppression function, detection is not affected by objects materials and background colors

Small blind zone (2-3mm), strong anti-interference ability and high stability

Industry Applications

Logistics and transportation industry: In logistics warehouses, packages vary in color, shape, and material. The sensor can accurately identify packages on the conveyor belt without being disturbed by the surrounding environment and other packages, enabling efficient sorting and inventory management.

Food and pharmaceutical industry: It can detect food packaging, medicine bottles, and other objects on the production line to ensure product quality and safety.

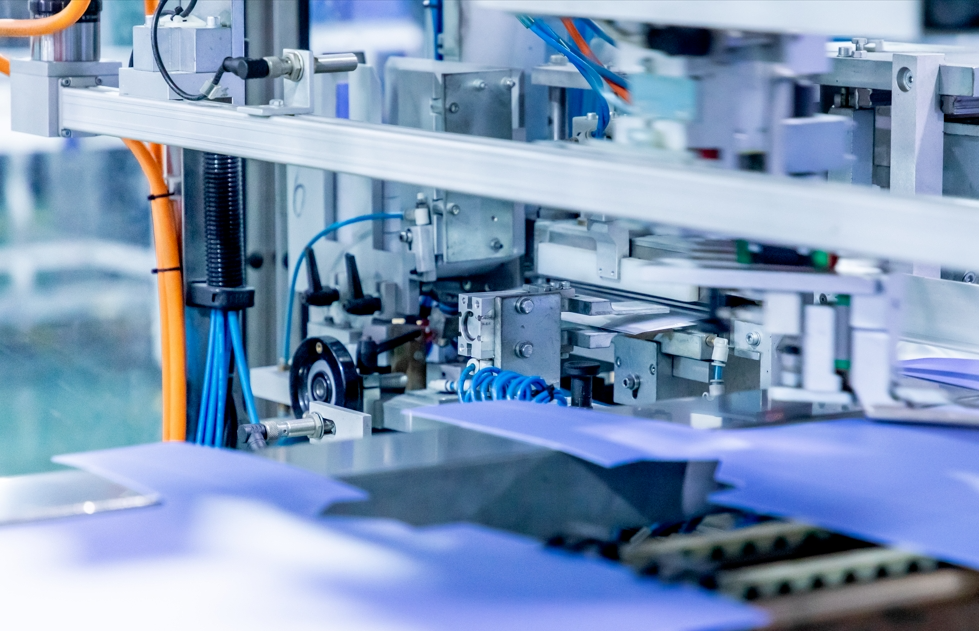

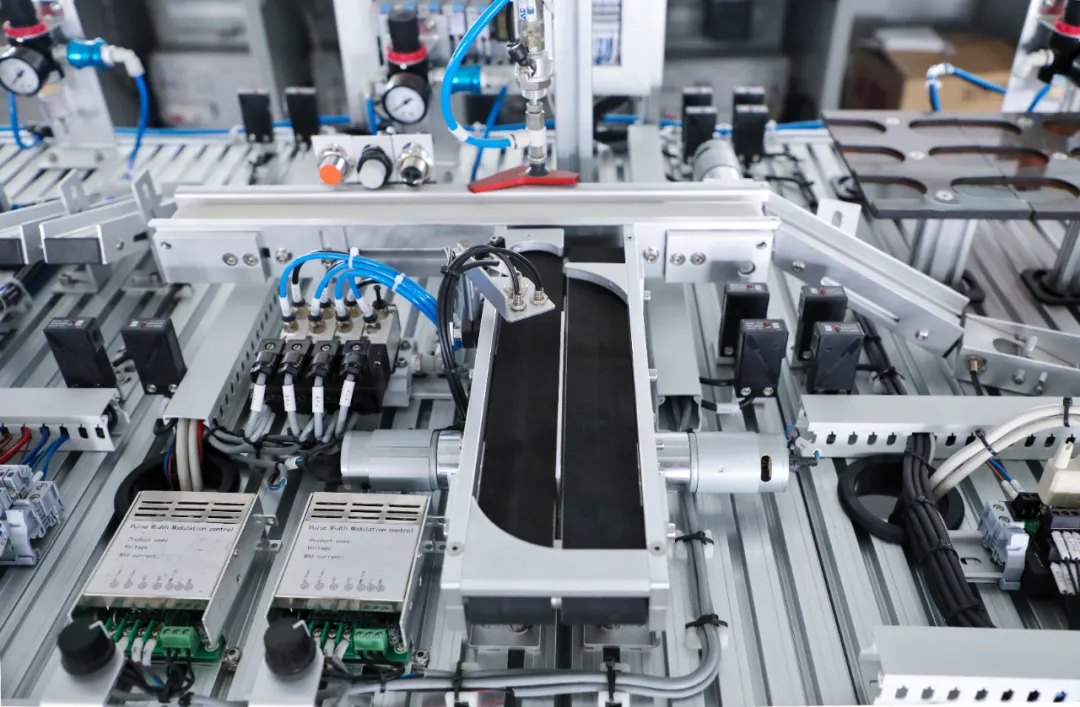

Mechanical manufacturing industry: On automated production lines of mechanical manufacturing, the square laser photoelectric sensor with background suppression can be used to check the position and existence of parts, monitor stacking height and material level, etc. It helps with automated assembly and improves production efficiency and precision.

Electronic manufacturing industry: Electronic components are tiny and come in various colors, such as chips and resistors. The sensor plays a key role in electronic component placement and detection, ensuring the quality of electronic products.

Product Application

![]()

Selection Tips

Detection distance: Choose a product with an appropriate detection distance based on the maximum and minimum distances between the target object and the sensor in actual application scenarios. For example, in the logistics industry, the distance between packages on the conveyor belt and the sensor varies greatly, so a sensor with a wide detection distance range is needed.

Light spot size: For detecting tiny objects, a sensor with a small light spot is selected; for detecting larger objects or in scenarios with holes or uneven surfaces, a sensor with a large or wide light spot is more suitable.

Response time: For scenarios involving the detection of fast-moving objects, a sensor with a short response time is required to meet the needs of high-speed detection

Related news