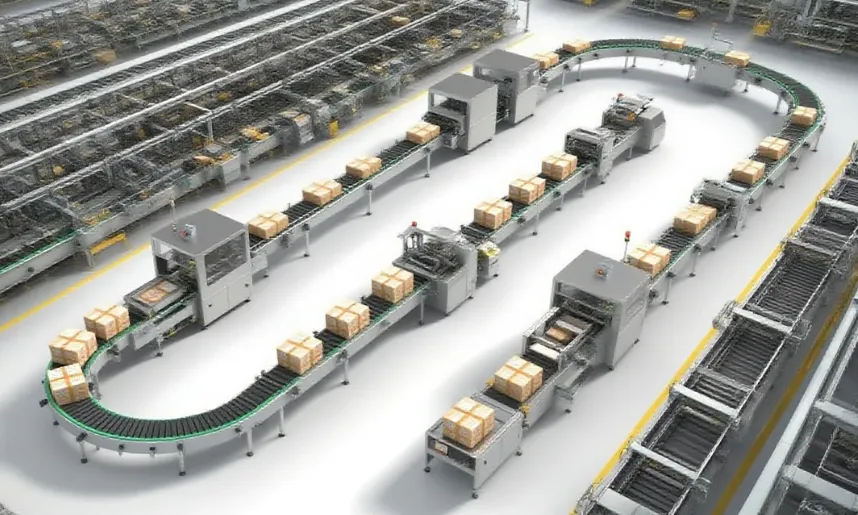

Solution | Application of Heyi Star Products in the Packaging Industry

Release time:2025-08-08

In today's industrial production, packaging automation has become a key link to improve production efficiency and ensure product quality. Various advanced sensors, as the "eyes" of packaging automation systems, play an indispensable role in it.

Heyi has accumulated rich experience in the research, development and application of sensor technology, and deeply understands the industry's desire for technological innovation and the pursuit of extreme production efficiency.

Today, we will show you some classic scenarios where Heyi sensors are applied in the packaging industry; through in-depth analysis of how to use advanced sensor technology combined with advanced automation equipment to achieve precise control of the packaging process, thereby improving production efficiency and product quality.

包装自动化

Scenario 1: Identifying the "presence or absence" of gaskets in beverage bottle caps

To accurately and efficiently complete complex packaging tasks.

Solution:

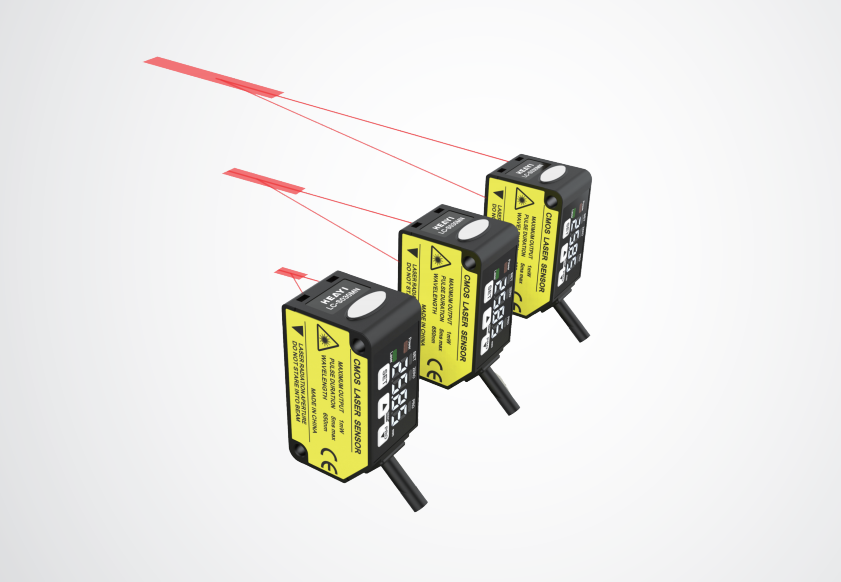

LC-S700RR CMOS laser displacement sensor

Technical advantages:

✅Measuring range: 700±500mm;

✅NPN/PNP can be freely switched; equipped with RS485 communication protocol;

✅Repeatability:

300μm(measuring distance 200mm-400mm)

800μm(measuring distance 400mm-600mm)

1000μm(measuring distance 600mm-1200mm)

✅Membrane keys for simpler operation; aluminum alloy shell for better durability;

✅White nixie tube displays distance value for clearer reading; large output indicator on the top for more intuitive observation.

Scenario 2

Product packaging inspection - product inspection and counting on food conveyor lines

To ensure the quality and safety of food production to the greatest extent.

Solution:

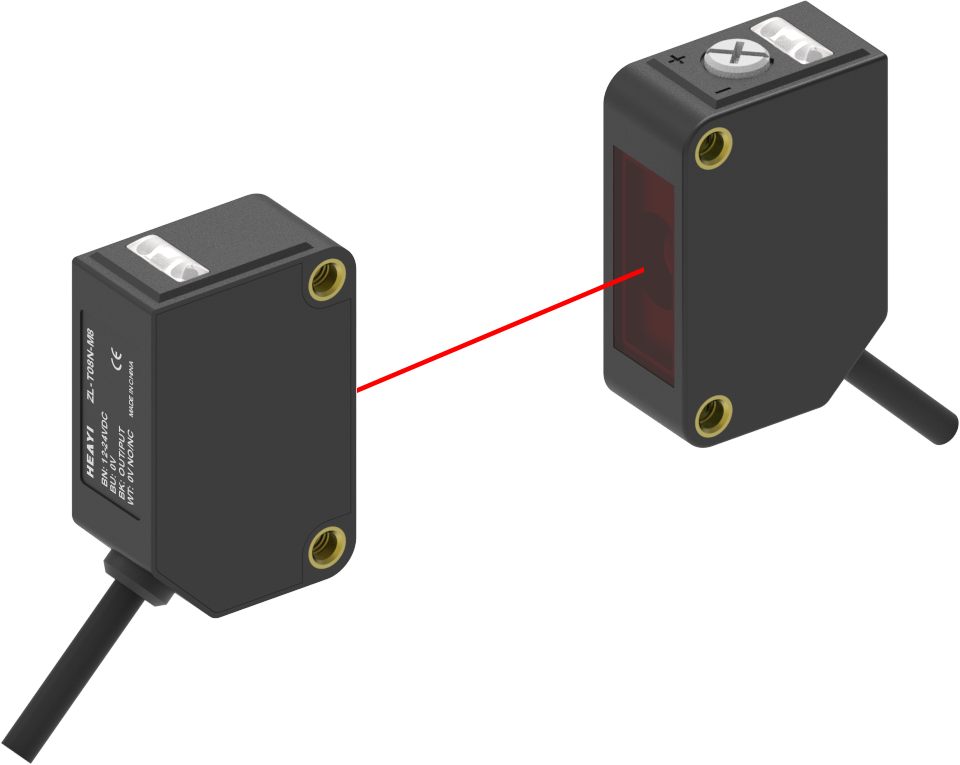

Ordinary red light and infrared photoelectric sensor ZL-T08N-M8

Technical advantages:

Detection distance: 8m;

✅Detected object: Φ10mm opaque object;

✅Response time: maximum 3ms;

✅Red LED with strong anti-interference and high stability;

✅Sensitivity adjustment: one-turn knob (230°).

饮料生

Beverage Production Automation

Scenario 1: Detection of "presence or absence" of beverage bottle caps

To improve beverage production efficiency with innovative sensors and automation solutions.

Solution:

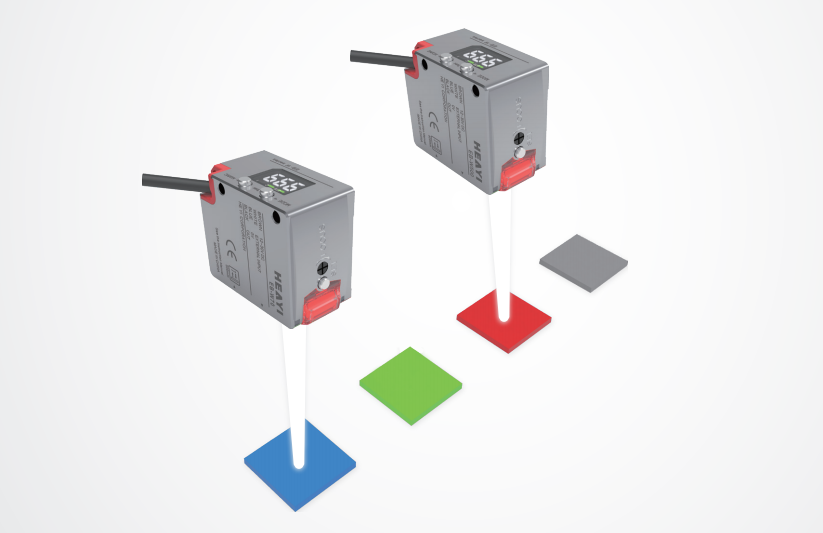

Long-distance color sensor EB-W500 series with white LED light source

Technical advantages:

✅White LED light source with wide wavelength, capable of stably detecting color or appearance differences;

✅Good anti-shake performance and equipped with background suppression function;

✅Can store 9 color samples at the same time;

✅Optional with IO-LINK communication; light spot can be modulated;

✅Detection distance: 50 to 500mm;

✅Response time: 200μs/1ms/10ms/100ms/500ms.

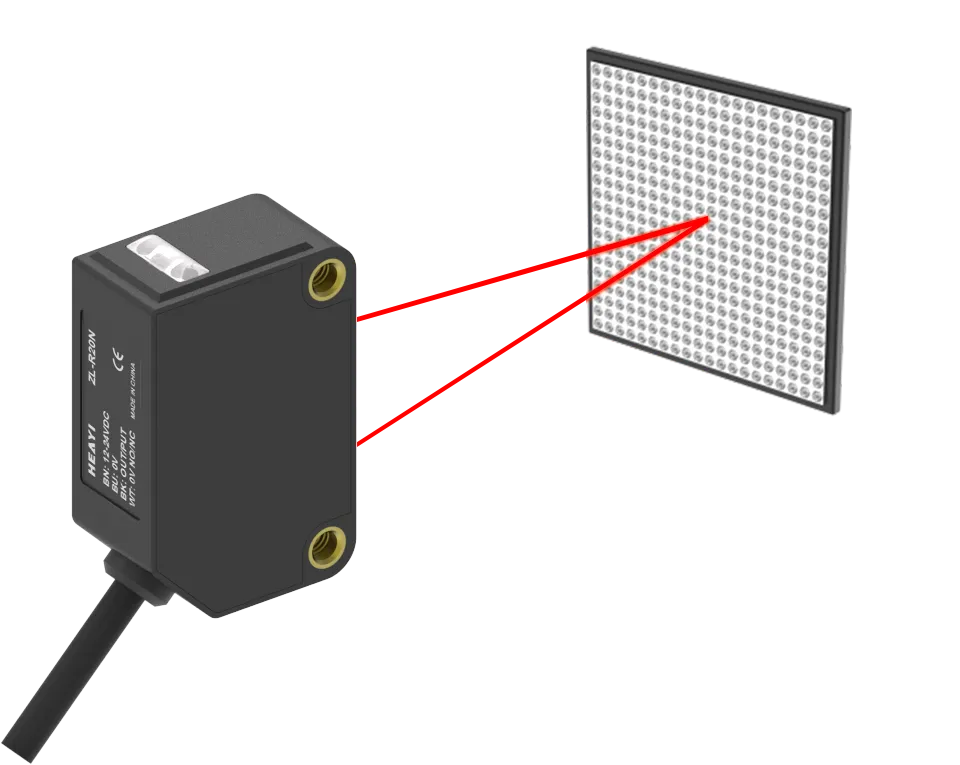

Scenario 2: Detection of transparent "films" and "transparent bottles"

To meet the high requirements and quality standards for transparent packaging detection in food, beverage and cosmetics industries.

Solution:

Ordinary red light and infrared photoelectric sensor ZL-R20N (polarized light) retro-reflective type

✅Red LED, retro-reflective type;

✅Detection distance: 1.5m;

✅Detected object: 45×45mm transparent object;

✅Sensitivity adjustment: one-turn knob (230°);

✅Response time: maximum 3ms.

Scenario 3: Label detection - detecting whether "product labels" have defects

Precise label detection to reduce the rate of energy damage and consumption.

Solution:

Photoelectric label sensor LA-B12 series

Technical advantages

✅High detection accuracy; based on photoelectric detection principle, can accurately detect opaque labels;

✅High-speed switching frequency and fast response speed; metal shell, sturdy and durable;

✅Long slot design for convenient label placement and detection;

✅Calibration value display and function operation error warning can be easily adjusted through closed calibration buttons or calibration output;

✅Adaptive logic circuit function (automatic level control) realizes optimal performance through independent optimization of switch thresholds.

化妆品包装

Cosmetics Packaging

Scenario: Detection of "color" and "sorting" of hose packaging

To promote the automation of the cosmetics and personal care industries to improve production efficiency.

Solution:

Integrated color mark sensor EB-S11 series

Technical advantages:

✅Compact size, with a 1.5*7mm linear light spot suitable for detection in different application environments;

✅Long detection distance, with a detection range of 18-28mm;

✅Equipped with two detection modes: color and color mark; two-point setting, simple and convenient;

✅High anti-shake performance; eliminate the impact of jitter on the detected object by adjusting precision;

✅Stable and reliable detection; accurately identify the edge of the detected object or the critical position of two different colors.

HeYi sensors provide targeted solutions to accurately meet the detection needs of various links in the packaging industry, provide solid technical support for enterprises' automation upgrading, and continuously promote the packaging industry towards a more efficient, precise and intelligent direction.

Want to learn more about sensor solutions for the packaging industry

August 28-30

You are cordially invited to attend

2025 China (Wenzhou) International Intelligent Printing & Packaging Industry Exhibition

Booth 7E221-222

Unlock more solutions on site

packing application

previous

Related news