Application Case: Laser Displacement Sensor LC-S700RR Boosts Efficiency for a Semiconductor Enterprise

Release time:2025-07-03

A leading semiconductor enterprise has long grappled with the issue of unexpected chip stacking during high-end chip manufacturing. This stacking problem not only causes frequent equipment downtime and process failures but also leads to mass rejection of high-value products, resulting in significant economic losses.

Project Challenge:

Micron-level Precision Requirements: Detecting chip stacking, which typically increases the height by just a few hundred microns, demands extremely high measurement accuracy.

High-speed Online Detection: The production line operates continuously at high speeds, requiring sensors with rapid response times to ensure seamless integration without disrupting the production rhythm.

Harsh Production Environment: Sensors must be adaptable to clean conditions and withstand minor vibrations, maintaining stable and reliable performance.

Non-contact Measurement: To prevent secondary damage or contamination, contact with the fragile chip surface must be avoided.

Reliable Anomaly Detection: There is a need for precise differentiation between the reference height of a single-layer chip and the abnormal height of stacked chips.

Solution

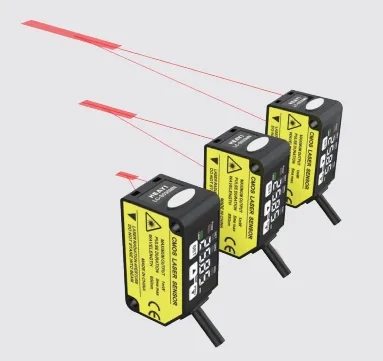

To address the challenges of chip stacking detection, the high-precision Laser Displacement Sensor LC-S700RR leverages its core advantages of non-contact, high-speed, and accurate measurement to provide an efficient and reliable solution, ensuring smooth production line operation and product quality.

Detection Principle and Core Advantages

Precise Anomaly Capture: When chips are laid out in a single layer, the surface height is set as the reference value (carrier height + chip thickness). The LC-S700RR accurately measures the real-time height through laser reflection. Once the measured value significantly exceeds the reference range (indicating stacking), it immediately triggers an anomaly signal.

Non-contact High-speed Measurement: The laser measurement method completely eliminates contact with the chip. Its ultra-fast response perfectly matches high-speed production lines, enabling 100% online detection.

Extensive and Flexible Output: With a measurement range of up to 700±500mm, it can easily cover wide tracks or large carriers. It offers switch output signals (NPN/PNP switchable) for direct control of alarms or shutdowns, and RS485 communication for convenient data upload and system integration.

Stable and Reliable Operation: Its robust design ensures long-term, trouble-free operation in semiconductor production environments.

Typical Application

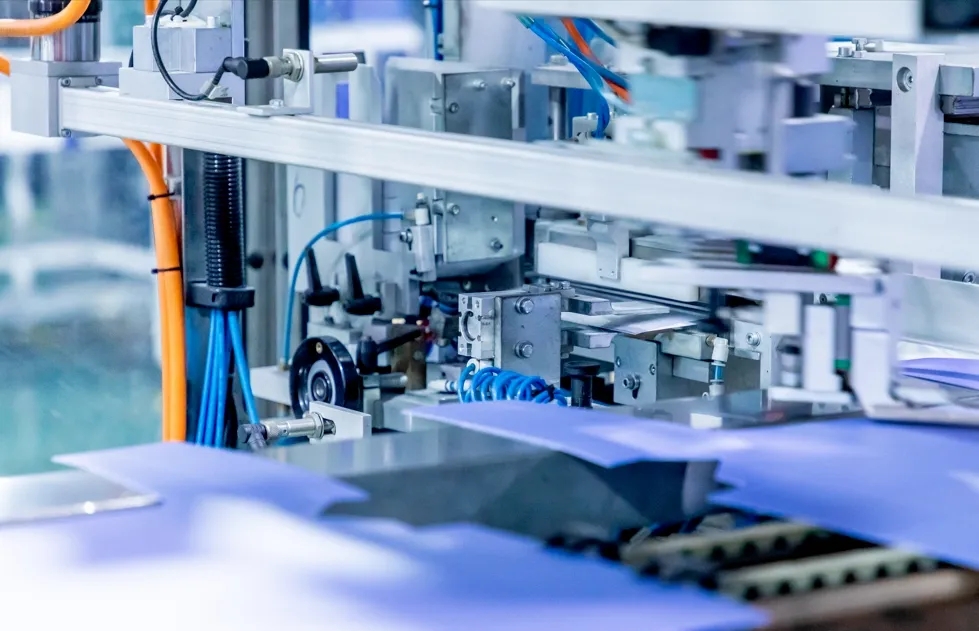

Real-time Stacking Monitoring on Transmission Tracks:

Chips are prone to accumulation and blockage due to static electricity or malfunctions during track transmission. By deploying the LC-S700RR above the track to continuously scan the cross-sectional height, when the sensor detects an abnormal height increase (stacking) in a local area, it immediately outputs an alarm signal, prompting timely intervention and effectively preventing production line interruptions and chip damage.

Product Parameters of Laser Displacement Sensor LC-S700RR

Measurement range: 700±500mm;

NPN/PNP can be freely switched;

Equipped with RS485 communication protocol;

Extended Application Scenarios

Thickness/Height Sorting and Discrimination of Precision Components: Such as identification of molds and hardware parts or position detection.

Monitoring of Large Coil Material Remainders: For example, precise measurement of the diameter of coils or the remaining film in the winding machines during new energy battery production.

Flatness Detection of Flat Glass and Wafers

previous

Related news