Application Case | EB-S11 Color Mark Sensor Powers Food Packaging Production Line Upgrade

Release time:2025-06-24

A Leading Food Enterprise Upgrades Production Line: Precision Cutting Solution for High-Speed Coil Packaging Equipment

Project Challenges:

1.The color marks on plastic packaging are small in area, and the packaging coil runs at extremely high speeds, causing traditional sensors to often lead to cutting position deviation.

2.Require ultra-short response time and rapid detection: Sensors must complete detection and output signals within an extremely short time to ensure accurate cutting.

3.Space constraints: The production line transformation needs to install new sensors in a narrow space without affecting the original mechanical structure.

Solution: Application of Color Mark Sensors in Coil Packaging Equipment

Color mark sensors are primarily used to detect specific color marks or spots on objects by comparing them with non-color mark areas.

1.Positioning and Sealing Cutting for Packaging Bags

Heyi color mark sensor EB-S11 series is commonly used for positioning and cutting control of packaging bags in coil packaging equipment. By setting specific color marks (such as black, white, or other high-contrast color lines) on the packaging bags, the sensor accurately identifies these marks and triggers the cutting mechanism to act at the mark position, ensuring precise cutting.

2.Improved Cutting Precision

The precise identification of color mark positions by the sensor significantly enhances cutting accuracy.

3.Rapid Response

With a reaction time of 100 microseconds, the sensor instantly sends a signal upon detecting the color mark, ensuring the cutting mechanism responds promptly.

4.Adaptability to Diverse Packaging Materials

The sensor adapts to various packaging materials, including aluminum foil films, high-pressure polyethylene films, etc. Despite differences in light transmittance, toughness, and stretchability, the sensor adjusts detection parameters and sensitivity to ensure accurate color mark identification and cutting on different materials.

5.Automated Production Realization

Combined with the automated control system of the coil packaging equipment, the color mark sensor enables full automation of the cutting process. When a color mark is detected, the sensor automatically sends a signal to the control system, which then activates the cutting mechanism—eliminating the need for manual intervention, improving production efficiency, and reducing labor costs.

6.Compact Design for Easy Installation

With a detection distance of 18–28 mm, the sensor can be directly mounted on the side of the guide roller bracket without modifying the mechanical structure.

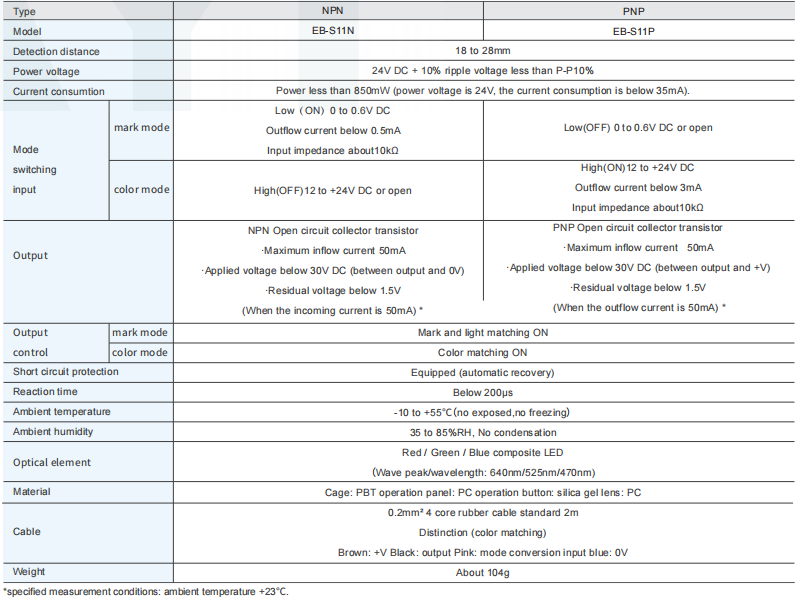

EB-S11 Series Integrated Color Mark Sensor Specifications

Extended Application Scenarios

Pharmaceutical Packaging: Precision cutting and positioning for tablet and capsule packaging bags.

Daily Chemical Packaging: High-speed assembly line cutting for toothpaste, laundry detergent, etc.

Food Packaging Line Expansion: Extendable to intelligent detection in carton sealing, inkjet coding, labeling, and other links.

Textile Industry: Detects color marks on fabrics during production and dyeing to control color consistency and pattern accuracy.

Printing Industry: Detects color marks on printed materials to adjust printing equipment parameters, ensuring color accuracy and overprinting precision.

Color Sensor,Aplication

previous

Related news