Application Case | Frequent Errors in Bolt Assembly at Automobile Factories? See How This Company Broke the Deadlock!

Release time:2025-06-18

In the engine assembly process of a large-scale automotive manufacturing enterprise, various bolts of different specifications are required. Although these bolts are similar in size, they need to be precisely distinguished due to differences in materials and torque requirements. In the traditional assembly mode, manual identification based on color markings on the bolt heads is not only inefficient but also highly prone to misjudgment.

Project Challenges:

Variable Assembly Positions: During automated assembly, bolts may shift or tilt (not vertically aligned). The sensor must stably detect them even when they are tilted or at relatively long distances.

Harsh Workshop Environment: Engine assembly workshops feature complex conditions, including oil stains, vibrations, and electromagnetic interference. Sensors need high protection ratings and anti-interference capabilities to ensure long-term reliable operation.

Precise Area Matching: The color-coded areas on bolt heads for identification are usually small. The sensor's light spot must accurately cover these areas to avoid unstable detection or false triggering caused by a light spot that is too large or too small.

Efficient and Stable Identification: With high-speed production lines, sensors must respond quickly and achieve high recognition accuracy.

Solutions

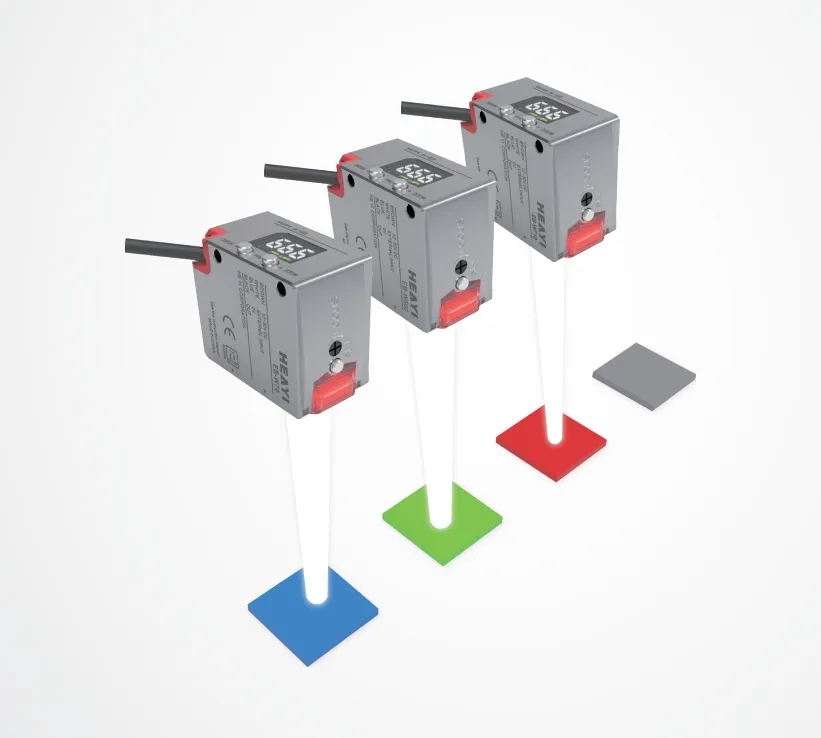

To meet the demand for bolt color identification in automotive engine assembly, the EB-W70/W500 series of long-distance color sensors with white LED light sources leverages its advantages in stable detection, high protection ratings, adjustable light spots, and background suppression to help enterprises overcome bolt detection challenges!

1、Overcoming Angle and Distance Variations:The EB-W70/W500 series of long-distance color sensors with white LED light sources support long-distance detection (with detection ranges of 70mm and 500mm) and have excellent detection angle tolerance. Even if bolts tilt slightly or the distance from the sensor changes during assembly, the sensors can stably lock onto color markings, ensuring reliable detection signal output and preventing false negatives or positives due to position fluctuations.

2.Precise Identification with White Light Source: Using a "white LED" light source, these sensors can quickly distinguish subtle color differences on bolt heads (such as various shades of blue, red, yellow, etc.) and provide accurate, consistent recognition results under various lighting conditions.

3.Adjustable Light Spot for Small Areas: The EB-W70/W500 series allows free adjustment of the light spot size. Operators can flexibly adjust the light spot diameter according to the actual size of the color-coded areas on different bolt heads, ensuring the light spot precisely covers the detection target area, achieving optimal detection results and the highest recognition accuracy while avoiding background interference.

4.Robust and Durable for Harsh Environments: Housed in zinc-cast shells, these sensors have an IP65 protection rating, effectively resisting oil stains, dust, water splashes, and common physical impacts in workshops. Their excellent shock resistance and anti-interference capabilities ensure long-term stable operation on engine assembly lines with complex vibration and electromagnetic environments, reducing maintenance requirements.

5.Improving Automation Efficiency and Quality: By accurately, quickly, and stably identifying bolt colors, the EB-W70/W500 series directly outputs signals to guide robots or assembly equipment to select the correct bolts for assembly. This completely replaces the error-prone manual identification process, significantly improving assembly accuracy, production efficiency, and reducing rework and risks caused by incorrect assembly.

EB-W70/W500 parameters:

Optional IO-LINK communication

Capable of storing 9 color samples simultaneously

Excellent anti-jitter performance with background suppression function

White LED light source with a wide wavelength range for stable color or appearance difference detection

Response time: 200μs/1ms/10ms/100ms/500ms

Light spot modulation available (EB-W70 offers single or dual light spots; EB-W500/WF70 allows light spot size adjustment)

可延展应用场景

Extended Application Scenarios

1.Automobile Final Assembly Lines: Identifying specific color-coded fasteners, wire harness connectors, or labels used in different parts of the vehicle body.

2.Component Sorting: Automatically sorting different types of components (such as gaskets, seals) according to color markings during incoming inspection or sub-assembly.

3.Other Industrial Assembly: Applicable to any automated assembly scenario where precise positioning, identification, or verification of components, labels, or markings based on color is required.

Related news