Application Case | UE-13 Series Ultra-Thin Photoelectric Sensors in Tray Detection for 3C Mobile Phone Manufacturing

Release time:2025-09-22

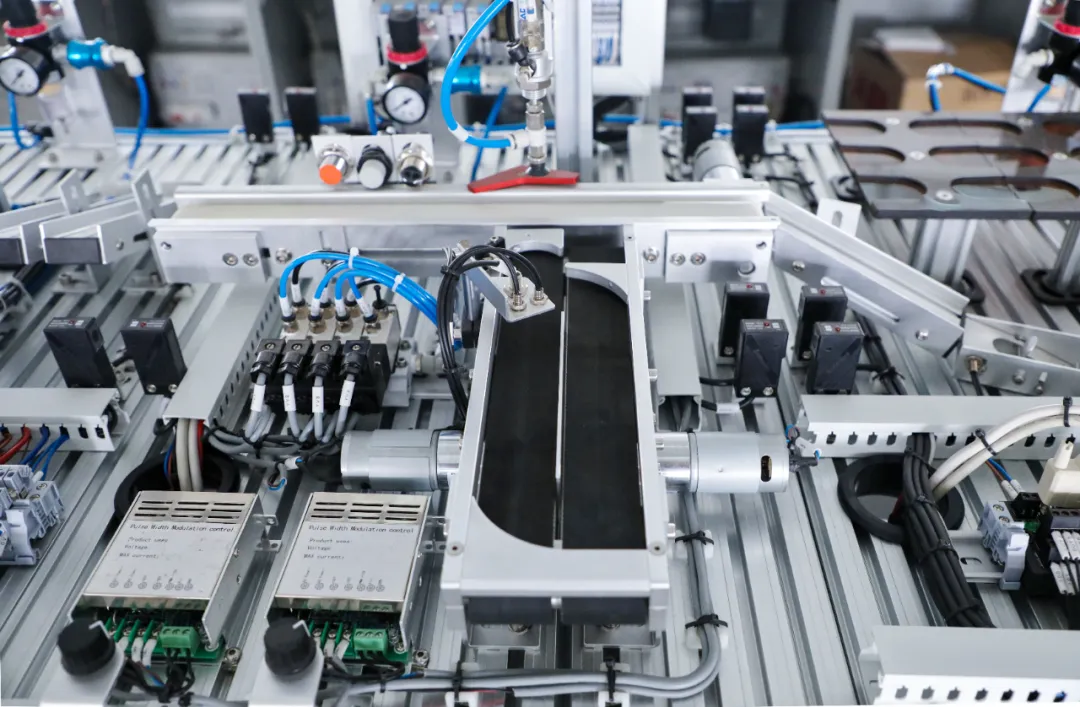

A well-known 3C mobile phone manufacturer required tray position detection on its production line. The trays on the line carry critical components for mobile phone manufacturing (including chips, screens, and other precision parts) and need to be moved accurately to designated positions to enable robotic arms to grab and assemble them precisely. Any positioning deviation may lead to production interruptions, component damage, or product quality issues.

Project Challenges

Space Constraints: Traditional sensors are relatively large and cannot be installed in the narrow space of the tray track.

Response Speed Requirement: High-speed production lines demand the sensor to complete detection and feed back signals within milliseconds.

Solution

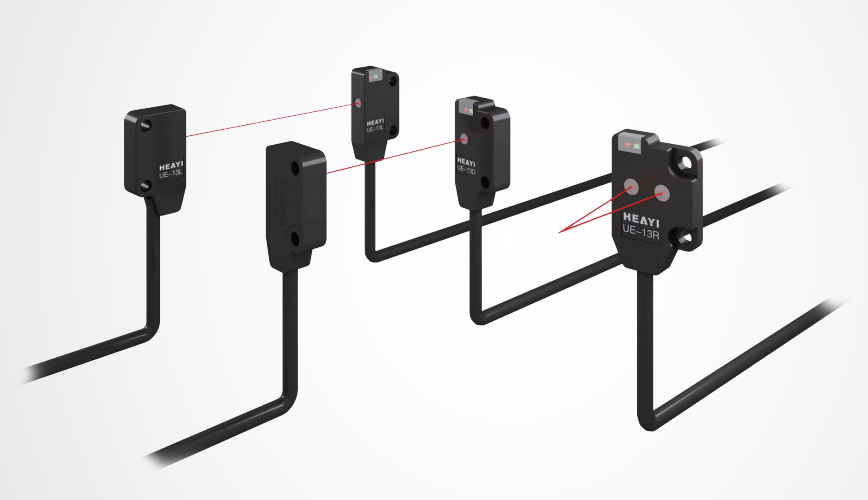

After a detailed evaluation, the UE-13 Series standalone ultra-thin photoelectric sensors were recommended to the customer. With its 5mm ultra-thin thickness, high precision, and fast response performance, this sensor perfectly meets the installation space and performance requirements of the production line.

Core Product Advantages

Ultra-Thin Design for Flexible Installation: The UE-13 Series standalone ultra-thin photoelectric sensor has a thickness of only 5mm, which can be easily embedded in the limited space on the side or top of the tray track. It requires no modification to the existing equipment structure, enabling easy installation without interfering with material flow.

1mm High-Precision Detection: The UE-13 can stably detect opaque objects of Φ1mm. By judging changes in optical signals, the sensor can accurately detect whether the tray is in place.

1ms High-Speed Response: The sensor can complete detection and output signals within 1ms, ensuring synchronization with the high-speed operating robotic arms and production rhythm, avoiding production delays, and improving overall efficiency.

Strong Anti-Interference Capability: The UE-13 has excellent anti-interference performance in complex environments, ensuring the reliability and continuity of detection signals in complex conditions.

Implementation Effects

By deploying the UE-13 Series ultra-thin photoelectric sensors, the customer successfully achieved accurate detection and real-time monitoring of the tray movement process:

✅ Production Line Efficiency Improved: No errors in tray position detection, and the grabbing accuracy of robotic arms was significantly enhanced.

✅ Product Quality Optimized: Component damage or assembly errors caused by positioning deviations were avoided.

✅ Maintenance Costs Reduced: The sensor has strong anti-interference capability and stable long-term operation, reducing downtime caused by faults.

Related news