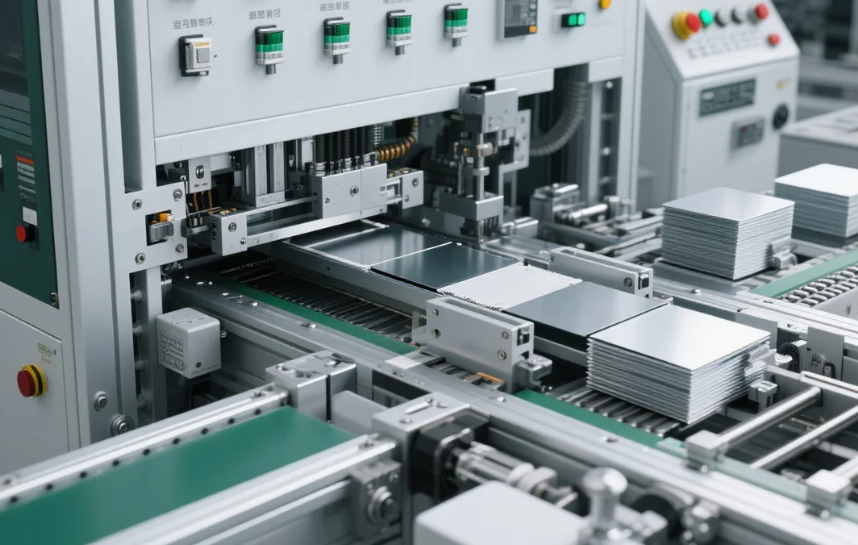

Laminating Machine (Lithium Battery Production) - Heyi Sensor Solutions

Release time:2025-09-10

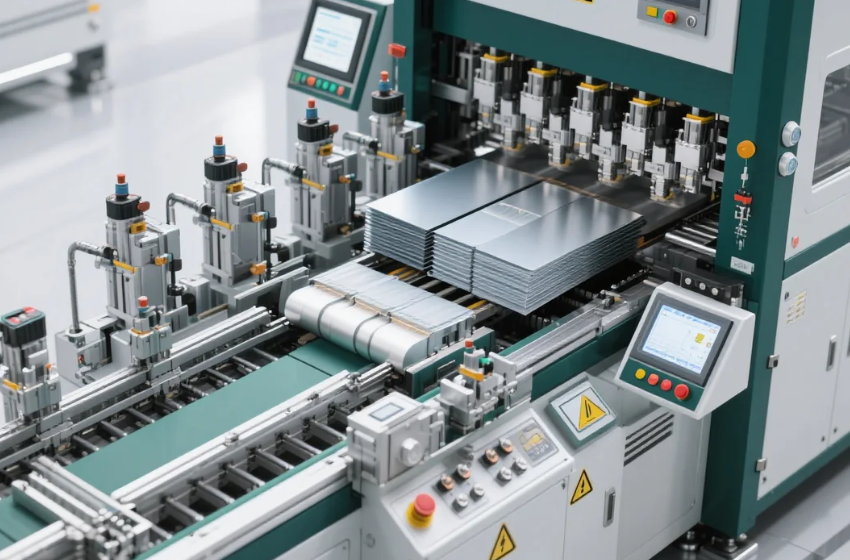

As a core piece of equipment in lithium battery manufacturing, the performance and precision of laminating machines directly determine battery quality and production efficiency.

To address this, Heyi is committed to integrating advanced sensing technology with in-depth lithium battery industry expertise, providing comprehensive and customized sensor solutions for lithium battery manufacturers.

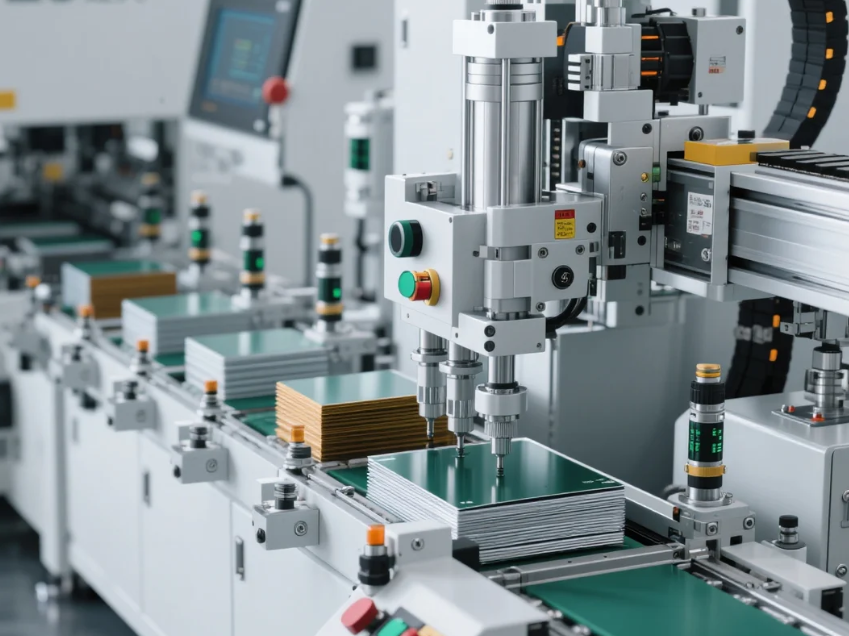

Scenario 1: Detection of Positive/Negative Electrode Sheet Positioning

Heyi Solution: Intelligent Digital RGB Color Sensor (EB-C1 Series) + Universal Sleeve-Type Reflective Sensor (FN-D110 Series)

Application: Sensors detect the position of battery electrode sheets. Once an electrode sheet is in place, the sensor triggers the next operation. Detection distance ranges from several millimeters to dozens of millimeters.

Technical Advantages:

✅ Accurate identification of subtle color differences, capable of distinguishing over 1,000 color shades precisely.

✅ 4-channel design, supporting simultaneous storage of 4 colors with sequential single-channel signal output.

✅ Multiple detection modes, suitable for various application scenarios.

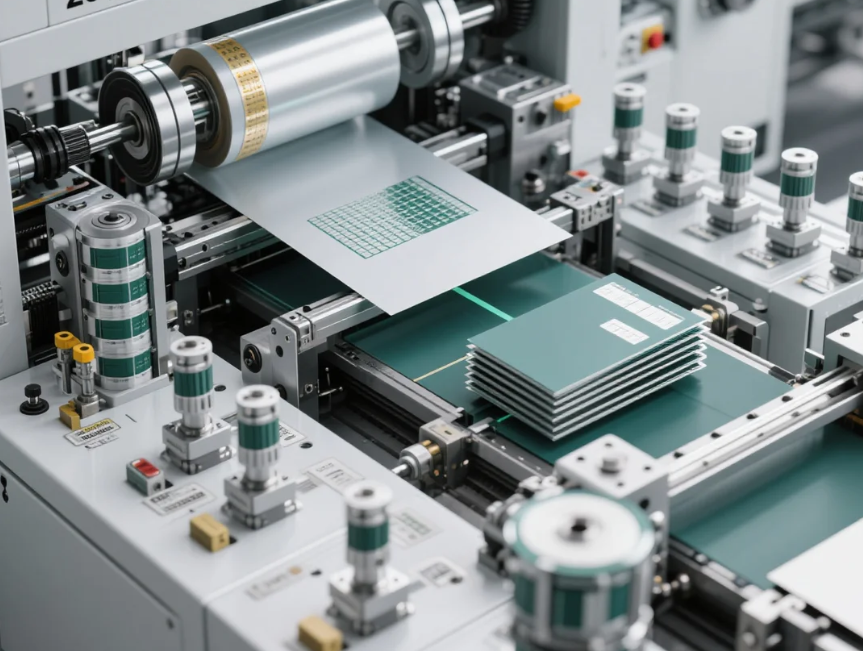

Scenario 2: Remaining Material Monitoring for Separator Feeding

Heyi Solution: CMOS Laser Displacement Sensor (LC-S Series)

Application: Used on laminating machines to monitor the remaining amount of lithium battery separators. When the separator roll is nearly exhausted, the sensor sends a signal to the equipment, prompting operators to replace the roll in a timely manner.

Technical Advantages:

✅ Three detection distance options (short, medium, long); compact size, small light spot, and high precision.

✅ Multiple output functions: single switching output, dual switching & analog output, and RS485 communication output.

✅ Diverse functions and detection modes, adaptable to more application scenarios.

✅ Aluminum alloy housing for enhanced durability; membrane buttons for simplified operation.

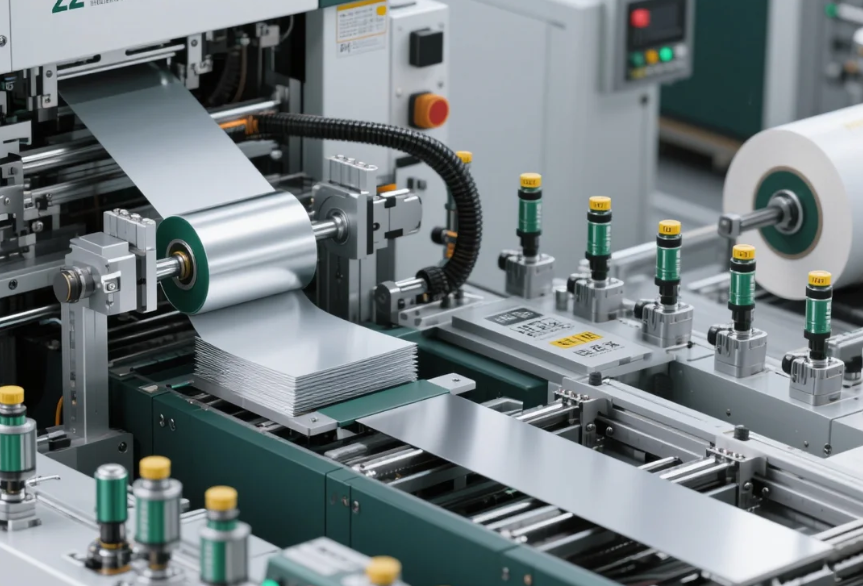

Scenario 3: Mechanism Limiting/Position Control

Heyi Solution: Slot-Type Photoelectric Sensor (UE-25/45 Series)

Application: In winding machines and laminating machines for the lithium battery industry, servo motors are often used for positioning control to facilitate position correction. A large number of these sensors are widely applied at multiple points inside the machine for origin/limit position control of mechanism modules and position control of roller shafts.

Technical Advantages:

✅ Built-in independently developed photoelectric chip by Heyi, featuring powerful functions, compact size, high anti-interference capability, and excellent stability.

✅ Multiple model options and high-speed response.

Scenario 4: Detection of Cylinder Expansion/Contraction Status

Heyi Solution: Magnetic Switch (C Series)

Application: Detects the expansion and contraction status of cylinders to verify normal cylinder operation, ensuring equipment stability during runtime.

Technical Advantages:

✅ Compact size, compatible with both small and large cylinders; multiple specifications for quick installation.

✅ High-sensitivity magnetoresistance with a repeat accuracy of 0.001mm.

✅ Integrally injection-molded structure for robustness and an elegant appearance.

✅ IP68 protection rating; all products can operate normally even when submerged in 20 meters of water, ensuring dust and water resistance.

Scenario 5: Label Color Detection

Heyi Solution: Long-Distance Color Sensor with White LED Light Source (EB-W500 Series)

Application: In winding machines and laminating machines for the lithium battery industry, it is often necessary to detect the presence of adhesive tapes on electrode sheets/separators to enable subsequent cutting or winding processes.

Technical Advantages:

✅ The EB-W500 Series (long-distance color sensor with white LED) accurately identifies tape colors and outputs corresponding signals.

✅ Excellent anti-vibration performance and built-in background suppression function. Even if tape jitters due to unstable tension, the sensor still stably detects tape colors and outputs signals.

Scenario 6: Remaining Material Monitoring for Electrode Sheet Feeding

Heyi Solution: Independent Ultra-Thin Photoelectric Sensor (UE-13 Series)

Application: Detects whether there are electrode sheets left in the electrode sheet magazine. When electrode sheets are exhausted, the sensor immediately sends a signal to trigger the equipment’s feeding process.

Technical Advantages:

✅ The UE-13 Series (independent ultra-thin photoelectric sensor) features an ultra-thin design, effectively solving the "space constraint" issue of equipment.

✅ Integrated positioning holes for easy installation.

✅ IP66 protection rating and superior mechanical performance.

Scenario 7: Operator Safety Protection

Heyi Solution: Universal Safety Light Curtain Sensor (GM-L Series)

Application: Protects operator safety. If an operator’s hand enters the working area, the robotic arm inside the equipment stops immediately.

Technical Advantages:

✅ The GM-L Series (universal safety light curtain sensor) is installed on both sides of the equipment door frame. If an operator’s arm enters the protected area, the machine detects it and stops immediately.

✅ Robust structural design for enhanced shock resistance and long service life; cost-effective model with competitive pricing, suitable for safety protection in equipment work areas.

previous

Related news