| Square photoelectric sensor in the application of automatic production line

Release time:2024-10-23

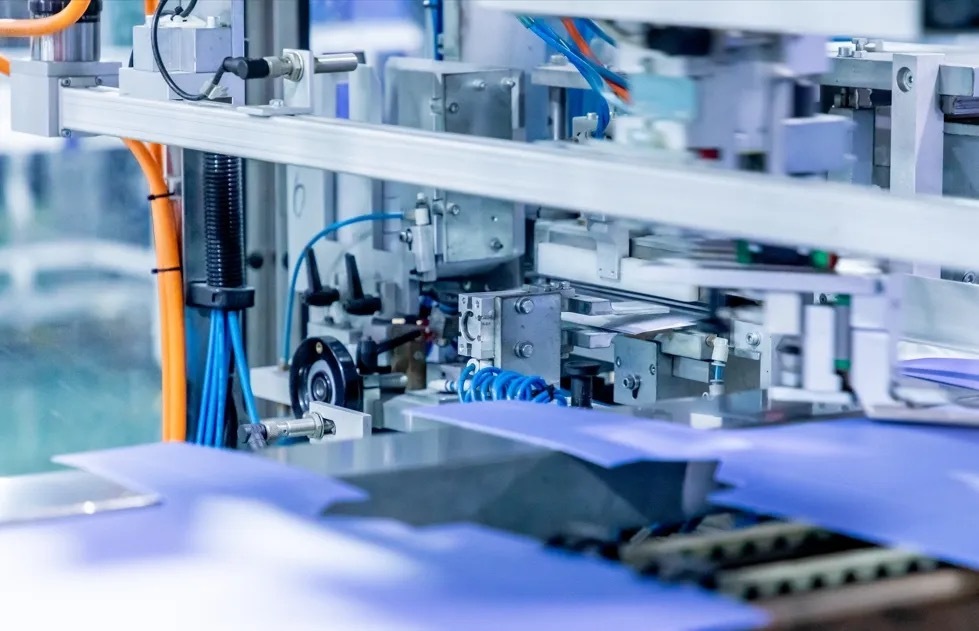

With the continuous development of industrial automation and intelligent manufacturing, accurate and efficient sensor technology is playing an increasingly important role in the production process. The square photoelectric sensor UL-D21/T21 series stands out in many industrial applications due to its high precision, stability and reliability. The application of the sensor in an automated production line will be described in detail in this case.

Project requirement

An automated production line requires precise testing of the products on the conveyor belt to ensure that each product meets quality standards. Specific requirements include:

1. Can accurately detect the presence of products on the conveyor belt.

2. Be able to identify the position and status of the product.

3. Achieve high-speed and high-precision detection to meet the efficiency requirements of the production line.

4. The sensor should have high stability and long life to reduce maintenance costs.

solution

For the above needs, you can choose HeYI square photoelectric sensor UL-D21/T21 series products.

The sensor has the following features:

• High-precision detection, using advanced photoelectric conversion technology, can accurately detect the presence and position of objects;

• Fast response, sensor response speed is fast, can meet the needs of high-speed production line;

• Good stability, reasonable sensor design, strong anti-interference ability, to ensure long-term stable work;

• Easy to install and debug, square appearance design, easy to install in various positions of the production line; At the same time, the sensor parameters can be adjusted to facilitate field debugging.

Implementation process

01, Install the sensor: according to the actual situation of the production line, choose the appropriate position to install the square photoelectric sensor UL-D21/T21 series. Ensure that the distance between the sensor and the conveyor belt is moderate for the best detection results.

02, debugging sensor: according to the characteristics of the product and the speed of the production line, adjust the parameters of the sensor, such as detection distance, sensitivity, etc. Ensure that the sensor can accurately identify the product on the conveyor belt.

03, connect the control system: the sensor and the control system of the production line are connected to achieve real-time data transmission and processing. When the sensor detects the product, the control system receives the signal and operates accordingly.

04, test and verification: Before the official operation of the production line, the sensor is comprehensively tested and verified. Ensure that the sensor can work properly under various conditions to meet the needs of the production line.

Application effect

By introducing the square photoelectric sensor UL-D21/T21 series, the automated production line achieves the following results:

• Improved detection accuracy, the sensor can accurately identify each product on the conveyor belt, effectively avoiding missed and false detection;

• Improved production efficiency, thanks to the fast response and high-precision detection of the sensor, the operating efficiency of the production line has been significantly improved;

• Reduced maintenance costs, the high stability and long life of the sensor reduces the probability of failure, thus reducing maintenance costs;

• Enhanced production safety, effectively preventing potential safety hazards through real-time monitoring of product location and condition.

The square photoelectric sensor UL-D21/T21 series has achieved remarkable results in the application of automated production lines. In the future, with the continuous development of intelligent manufacturing technology, we will continue to explore the application of sensor technology in more fields, and inject new vitality into industrial automation and intelligent manufacturing.

Related news